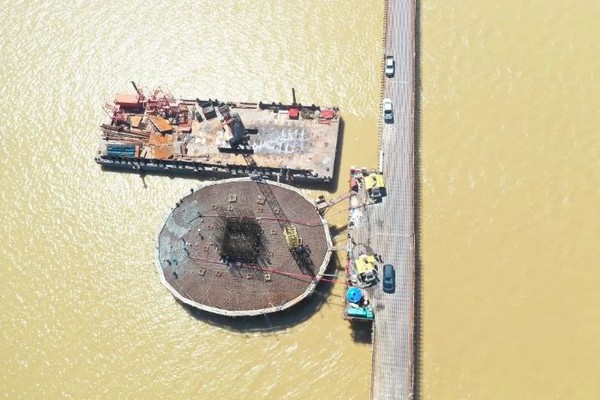

The Lhasa Estuary Bridge project in Malaysia is a major project led by the government of Sarawak State in Malaysia. The total investment of the project is about 560 million US dollars and the construction length is 2430 meters. When completed, it will become the longest bridge in Sarawak Prefecture, completely changing the traffic conditions of local residents who rely on ferries.

Sarawak has a all-year-round hot and humid climate and a long rainy season, and the pouring operation is generally as short as a few hours or as long as a few days, which undoubtedly brings great challenges to the equipment operation.

In order to cope with the harsh climatic conditions, XCMG HBT9018V concrete pump has made customized improvements in heat dissipation, heat resistance, waterproofing and moisture protection to ensure that the equipment can work for a long time in the environment of high humidity and high temperature.

Different from the previous construction of the cross-river bridge, the construction contractor built a Bailey bridge (a simple steel bridge) for material transportation and pier pouring. While it can bring convenience, there is also some trouble -- that is, the space for machines is relatively limited. but the “petite” XCMG HBT9018V drag pump shows its skill here.

Even the narrow pouring platform can simultaneously hold two XCMG HBT9018V towing pumps to feed while not affecting the passage of other transport vehicles, which not only reduces the safety risk, but also improves the construction efficiency.

Adapt to everywhere it goes

Although the body of XCMG drag concrete pump is small

it has great energy and great wisdom

HBT9018V is equipped with a number of the world's leading “cool techs”, such as efficient skirt valve pumping system, reliable hydraulic commutation technology, ultra-low pressure loss hydraulic system technology, etc., making it “small but powerful”!

Under continuous high-intensity construction operation, XCMG HBT9018V drag concrete pump’s excellent performance of safety and efficiency, earned high recognition from customers:

“XCMG equipment is so powerful that each pouring operation can be completed 2-3 hours ahead of schedule. From the beginning of the pouring to the present, there has not been a failure of each of the two drag pumps!”

In the future, XCMG will adhere to the internationalization strategy, continue to focus on products and technology, create more overseas localized products with core competitiveness, and create higher value for customers!