The Montenegro Bar-Boljare Highway is the major project in cooperation of China-Central & Eastern European Countries. The project connects the southern port city BAR in the south of Montenegro Republic and its northern city BOJIARE. As the first highway in the country, it will be part of the international highway network upon completion that connects many countries in the Central and Eastern Countries, thus having great significance for stimulating economic growth in the Montenegro Republic. After discussed and studied for many times, the Montenegro Bar-Boljare Highway project department decided to select XTR260 cantilever type tunnel boring machine to dig the tunnels. The Section Four in the project, where XTR260 worked, was constructed by CCCC Tunnel Engineering. Located in Kolasin in the north of Montenegro, Section Four is 9.066km long. Having four lanes in two directions, 72% of the section has bridges and tunnels with tunnels accounting for 50%. XTR260 cantilever type tunnel boring machine, because of its “leading technologies, reliable quality and premium service”, as rated as the Star Machinery in Montenegro Bar-Boljare Highway Project by the project department of CCCC Tunnel Engineering.

Montenegro Prime Minister Milo Đukanović was visiting the tunnel construction site in Montenegro Bar-Boljare Highway Project

On May 27, the left and right parts of the Pajkov Vir Tunnel along Montenegro Bar-Boljare Highway were broken through. The tunnel has the flysch surrounding rock stratum. With developed beddings, shallow burying and bias, the construction used the XTR260 cantilever type tunnel boring machine of XCMG to make mechanic operations. Till today, XTR260 has been used to work on six tunnels in the Montenegro Bar-Boljare Highway Project and the make through four tunnels in the project. The XTR260 boring machine is featured by large span of cutting arm with the cutting height reaching 7.1 meters. The large-section excavation can be formed once for all. The single-spiral small-diameter hard-rock cutting head has the optimal cutting pick distribution and cutting angle, with strong ability of rock-breaking. In the Montenegro Bar-Boljare Highway, two tunnels were dug at the same time, meaning the boring machine walked for a long distance. The auto winding electric controls system, combined with the elevated MDOF cable, can ensure automatic letting go and getting back cables in the machine walking, thus replacing manual work and protecting the cables while improving construction efficiency. It provides 380V/660V power supply options to meet different needs for tunnel construction, thus solving the problem of unstable power supply in the Republic Montenegro. It can switch to the soft start technology at any time to improve lifecycle and reliability of electric control system. The detached rotary platform connection mechanism is featured by easy installation and repair. With wireless remote control, electric leakage detection, fault alarm, safety protection and other intelligent technologies, it adopts the electro-hydraulic components of world-famous brand, human-oriented design, safe and reliable operations. The broad-width crawler rail drive/walk mechanism can adapt to various bases.

XCMG boring machine was working in Montenegro Bar-Boljare Highway

The Section Four in Montenegro Bar-Boljare Highway Project is mostly the flysch, with maximum compressive strength of the rocks at about 50Mpa. At present, the progress indicator realized by XTR260 is 0.8-1.5m/h on the upper stairs, which can roughly save nine months of construction period. Because the explosion procedure in Montenegro has complex procedure and must be operated by the special explosion staff, progress in other sections has been delayed seriously. By using XTR260, the Section Four avoided using explosives so as to reduce the safety threats and risks in progress. The equipment needs only two operators, meaning each shift in single tunnel excavation can save 13 operators. The boring machine also greatly reduces the surround rock interference, with the average linear digging going down from 20cm to about 5cm. It is estimated that the item alone can save about 350euros per meter for the cost of sprayed concrete.

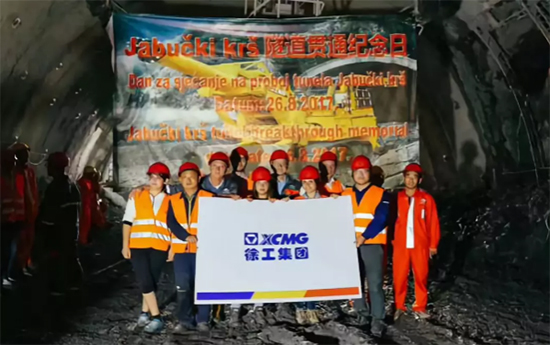

On August 28, 2017, the Tunnel Jabuka in Montenegro Bar-Boljare Highway Project was broken through

In the construction process, governments of the two countries paid great attention to its progress. On the evening of July 7, 2018, the Premier Li Keqiang of China met the Montenegro Prime Minister Milo Đukanović in Sofia, the capital city of Bulgaria. He pointed out that Montenegro Bar-Boljare Highway Project is the flagship project in the practical cooperation between the two countries, hoping the two parties work hard to speed up the construction progress and establish a model for the big-project cooperation between the two countries. The Republic Montenegro Prime Minister Milo Đukanović, Minister of the Transport of Montenegro, Ambassador Cui Zhiwei of China in Montenegro and Montenegro Commission of Science and Technology visited the construction site, giving high praise to the construction of boring machines. The Republic Montenegro TV also made a special report on the boring machines working in the tunnel construction.